Socket Weld Flanges, Socket Weld Flanges Manufacturers, Socket Weld Flanges Exporters, Socket Weld Flanges Suppliers, Socket Weld Flanges Stockists. ASME B16.5 SWRF Flanges Dimensions, Manufacturer of Carbon Steel Socket Weld Flange in India.

Socket Weld Flanges Specification

Standard : Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel ASTM A182 F5, F9, F11, F22, F91

Stainless steel ASTM A182 F304/L, F316/L

Outer Diameters:1/2 inch to 24 inch, up to 2500#

Schedule: SCH10, SCH 40, SCH 80, SCH 160 To SCH XXS

Pressure Ratings: Class 150 to Class 2500

Type: RF, RTJ

Coating: 3LPE, FBE, Varnished, Black, Zinc Coated

ASME B16.5 Socket Weld Flange are commonly utilized on more direct sizes of high-pressure pipes. These think about a smooth bore and better progression of the liquid or gas inside the line. Tempered Steel Socket Weld Flange are added by embeddings the line into the association end and applying filet weld around the top.

ASME B16.5 Socket Weld Flange. We are passing on Socket Weld Flange, Socket Weld Raised Face Flanges, Aluminum Socket Weld Flange and Socket Weld Flange Weight expecting all around that truly matters, zero effort because of sensible worker hours in India and extraordinary wellspring of shocking ANSI B16.5 Class 150 Socket Weld Flanges, most ideal circumstance, cost open in Mumbai, India.

Socket Weld Flanges Manufacturers in Mumbai, Socket Weld Flanges Exporters in Mumbai, Socket Weld Flanges Suppliers in Mumbai, Socket Weld Flanges Stockists in Mumbai. Contact Us for Latest Price List of Stainless Steel SWRF Flange, ASME B16.47 Series a Socket Welded Flange, Socket Weld Reducing Flange manufacturer in India, Check ASME B16.5 Class 300 Socket Weld Flange Dimensions

Omaa Metal Sources, We are making and suppliying Reducing Socket Weld Flange from most recent 20 years in India. You Can Check 300# Socket Weld Flange Dimensions and Class 150 Socket Weld Flange Dimensions. We have most basic store of 1 inch Socket Weld Flange and Code 62 Socket Weld Flange in India. Our Socket Weld Flange Rating will assist you with purchasing right Stainless Steel Reducing Socket Weld Flange. Solidified Steel Socket Weld Flanges understood by Saudi Aramco. We keep up wide effectively of Socket Weld Raised Face Flange.Omaa Metal Sources stock without a doubt level of ASME B16.5 Swrf Flanges, Flat Face Socket Weld Flanges in Stock in different sizes.

In the event that you are hoping to purchase ANSI B16.5 Socket Weld Flanges, most ideal circumstance, cost in India, check our cost of Stainless Steel Socket Weld Flange including Class 300 Socket Weld Flange, Socket Weld Ring Joint Flange and 3 Inch Socket Weld Flange. Connection Weld Forged Flanges to UK, USA, Sweden, Israel, France, Italy, Canada, UAE, Australia, Germany, Russia, Oman, Kuwait, Qatar, Iran, Turkey, Egypt, Bahrain, Indonesia, Malaysia, Singapore, Thailand, Sri Lanka and Saudi Arabia.

We can without a doubt Stainlees Steel Socket Weld Flange, most ideal circumstance, cost as we are perhaps the most incredible provider and merchant of Alloy Steel Socket Weld Flanges in Indium. We have our stocking merchants in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our Nickel Alloy 2500 Lb Socket Weld Flange cost going before purchasing Carbon Steel Socket Weld Flange from India or China. other than mail for our live deftly of Mss Sp-44 Socket Weld Pipe Flange to check types and sizes with our set up stock we can give you best cost of Inconel Socket Weld Reducing Flange.

We can besides give free illustration of Hastelloy Socket Weld Sae Flange,Omaa Metal Sources is having our Dealer and Distributor in Bangalore, Karnataka, Chennai (Madras), Tamil Nadu, Ahmedabad, Gujarat, Delhi, Pune, Maharashtra, Rajkot, Ghaziabad, Uttar Pradesh, Bhosari, Ludhiana, Punjab, Vadodara, Aurangabad, Faridabad, Gurgaon, Haryana, Indore, Madhya Pradesh, Jaipur, Rajasthan, Kolkata, West-Bengal, Khopoli, Karnataka, Kolhapur, Nagpur, Raipur, Chhattisgarh.. So on the off chance that you are searching for best cost of Socket Pipe Weld Neck Flange or Copper Nickel Swrf Flanges, Carbon Steel Socket Weld Flange close to you with most brief timeframe headway or free illustration of Rtj Socket Weld Flange.

Specification of Socket Weld Flanges

| ASME B16.5 Socket Weld Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Socket Weld Pipe Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Socket Weld Reducing Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Socket Weld Rtj Flange |

| SWRF Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Socket Weld Reducing Flange |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K SWRF Flanges |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Socket Weld Pipe Flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar Socket Weld Sae Flange |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of Socket Weld Hub Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates |

EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design |

As per your drawing

AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS,

NFE etc.

|

| Socket Weld Pipe Flange Uses & application |

|

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Material of Socket Weld Flange

-

Carbon Steel Socket Weld Rtj Flange

- A105 Socket Weld Flange

-

Alloy Steel High-Temp SWRF Flanges

- A182 Gr F1 Socket Weld Pipe Flange

- A182 Gr F11 Socket Weld Reducing Flange

- A182 Gr F12 Socket Weld Rtj Flange

- A182 Gr F22 Socket Weld Flange

- A182 Gr F5 Socket Weld Hub Flange

- A182 Gr F9 SWRF Flanges

-

Alloy Steel Low-Temp Socket Weld Sae Flange

- A350 Gr LF2 Socket Weld Reducing Flange

- A350 Gr LF3 Socket Weld Flange

-

Austenitic Stainless Steel Socket Weld Flange

- A182 Gr F304 Socket Weld Sae Flange

- A182 Gr F316 SWRF Flanges

- A182 Gr F321 Socket Weld Reducing Flange

- A182 Gr F347 Socket Weld Flange

- A182 Gr F304L Socket Weld Pipe Flange

- A182 Gr F316L Socket Weld Rtj Flange

- A182 Gr F317 SWRF Flanges

- A182 Gr F317L Socket Weld Reducing Flange

- A182 Gr F321 Socket Weld Pipe Flange

- A182 Gr F310 Socket Weld Hub Flange

- A182 Gr 347 Socket Weld Flange

-

Nickel Alloy Socket Weld Reducing Flange

- ASTM B564 Socket Weld Hub Flange

- astm b564 uns n06600 Socket Weld Reducing Flange

- astm b564 uns n06625 Socket Weld Sae Flange

- astm b564 uns no4400 SWRF Flanges

- astm b564 uns n08810 Socket Weld Reducing Flange

- astm b564 uns n08811 Socket Weld Pipe Flange

- astm b564 uns n08825 Socket Weld Flange

- astm b564 uns n04400 SWRF Flanges

- astm b564 uns n10276 Socket Weld Rtj Flange

- astm b564 uns n10665 Socket Weld Hub Flange

-

Titanium Socket Weld Sae Flange

- astm b381 grade f2 Socket Weld Hub Flange

- astm b381 f5 Socket Weld Rtj Flange

- astm b381 f3 Socket Weld Flange

- astm b381 f12 SWRF Flanges

- astm b381 f7 Socket Weld Reducing Flange

- Other grades: ASTM B381 F1, F2, F2H, F3, F4, F5, F6, F7, F7H, F9, F10, F11, F12, F13, F14, F15, F16, F16H, F17, F18, F19, F20, F21, F23, F24, F25, F26 , F26H, F27, F28, F29, F30, F31, F32, F33, F34, F35, F36, F37, F38 Socket Weld Pipe Flange

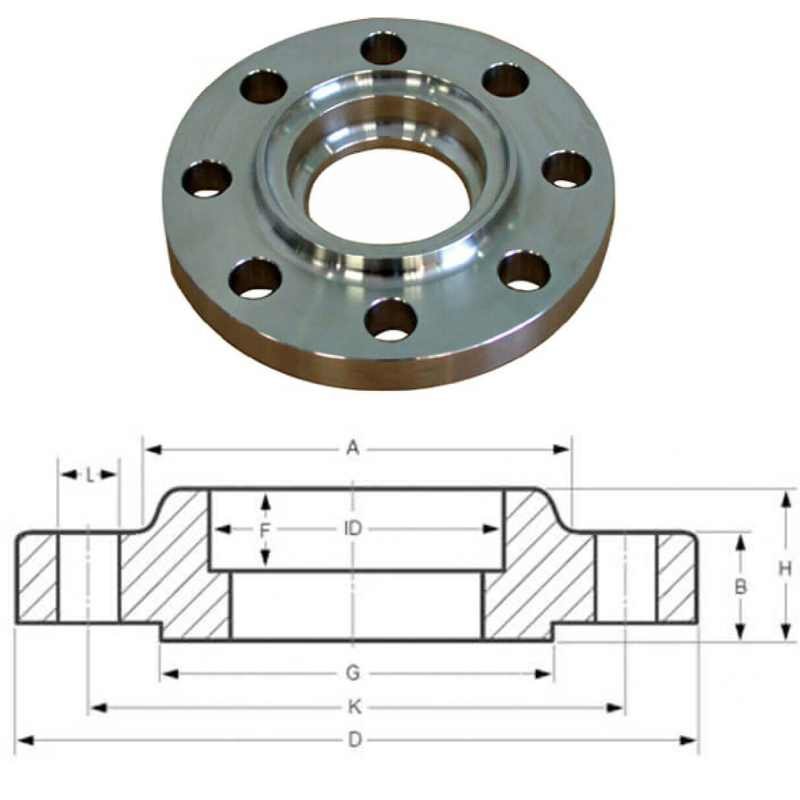

Dimensions of Socket Weld Flange

150 lb socket weld flange dimensions

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Socket Weld | Dia.(D) | Thick.(E) | Dia.(F) | Dia.(B) | Dia.(A) | Height1(H) | Nbr | Holes | Dia.(C) |

|

1/2″

|

90

|

11.2

|

35.05

|

30

|

22.2

|

14

|

4

|

15.87

|

60.3

|

|

3/4″

|

100

|

12.7

|

42.92

|

38

|

27.7

|

14

|

4

|

15.87

|

69.9

|

|

1″

|

110

|

14.3

|

50.80

|

49

|

34.5

|

16

|

4

|

15.87

|

79.4

|

|

1 1/4″

|

115

|

15.9

|

63.50

|

59

|

43.2

|

19

|

4

|

15.87

|

88.9

|

|

1 1/2″

|

125

|

17.5

|

73.15

|

65

|

49.5

|

21

|

4

|

15.87

|

98.4

|

|

2″

|

150

|

19.1

|

91.94

|

78

|

61.9

|

24

|

4

|

19.05

|

120.7

|

|

2 1/2″

|

180

|

22.3

|

104.65

|

90

|

74.6

|

27

|

4

|

19.05

|

139.7

|

|

3″

|

190

|

23.9

|

127.00

|

108

|

90.7

|

29

|

4

|

19.05

|

152.4

|

300 lb socket weld flange dimensions

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Socket Weld | Dia.(D) | Thick.(E) | Dia.(F) | Dia.(B) | Dia.(A) | Height1(H) | Nbr | Holes | Dia.(C) |

|

1/2″

|

90

|

11.2

|

35.05

|

30

|

22.2

|

14

|

4

|

15.87

|

60.3

|

|

3/4″

|

100

|

12.7

|

42.92

|

38

|

27.7

|

14

|

4

|

15.87

|

69.9

|

|

1″

|

110

|

14.3

|

50.80

|

49

|

34.5

|

16

|

4

|

15.87

|

79.4

|

|

1 1/4″

|

115

|

15.9

|

63.50

|

59

|

43.2

|

19

|

4

|

15.87

|

88.9

|

|

1 1/2″

|

125

|

17.5

|

73.15

|

65

|

49.5

|

21

|

4

|

15.87

|

98.4

|

|

2″

|

150

|

19.1

|

91.94

|

78

|

61.9

|

24

|

4

|

19.05

|

120.7

|

|

2 1/2″

|

180

|

22.3

|

104.65

|

90

|

74.6

|

27

|

4

|

19.05

|

139.7

|

|

3″

|

190

|

23.9

|

127.00

|

108

|

90.7

|

29

|

4

|

19.05

|

152.4

|

600# socket weld flange dimensions

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore Socket Weld | >Dia.(D) | Thick.(E) | Dia.(F) | Dia.(B) | Dia.(A) | Height1(H) | Nbr | Holes | Dia.(C) |

|

1/2″

|

95

|

14.3

|

35.05

|

38

|

22.2

|

22

|

4

|

15.87

|

66.7

|

|

3/4″

|

115

|

15.9

|

42.92

|

48

|

27.7

|

25

|

4

|

19.05

|

82.6

|

|

1″

|

125

|

17.5

|

50.80

|

54

|

34.5

|

27

|

4

|

19.05

|

88.9

|

|

1 1/4″

|

135

|

20.7

|

63.50

|

64

|

43.2

|

29

|

4

|

19.05

|

98.4

|

|

1 1/2″

|

155

|

22.3

|

73.15

|

70

|

49.5

|

32

|

4

|

22.22

|

114.3

|

|

2″

|

165

|

25.4

|

91.94

|

84

|

61.9

|

37

|

8

|

19.05

|

127.0

|

|

2 1/2″

|

190

|

28.6

|

104.65

|

100

|

74.6

|

41

|

8

|

22.22

|

149.2

|

|

3″

|

210

|

31.8

|

127.00

|

117

|

90.7

|

46

|

8

|

22.22

|

168.3

|

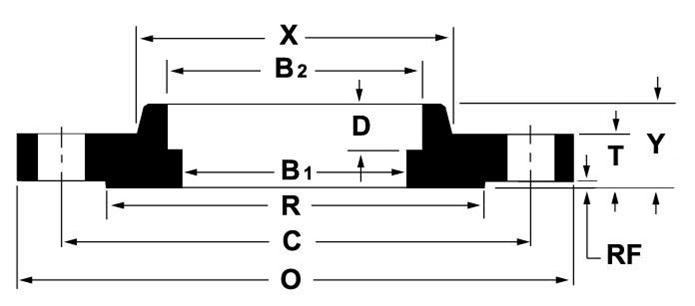

Weight Chart Of Socket Weld Flange

|

NPS (Inches) |

DN (mm) |

FLANGE OD A MM |

FLANGE THICKNESS D MM |

SLIP ON FLANGE WEIGHT (KGS) | WELD NECK FLANGE WEIGHT (KGS) | BLIND FLANGE WEIGHT (KGS) |

| 1/ 2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/ 4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/ 4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/ 2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/ 2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/ 2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |