310 Grade Stainless Steel Is A Medium Carbon Based Austenitic Stainless Steel. The Primary Alloying Elements Used In The Stainless Steel 310 Fasteners Include About 25% Chromium And 20% Nickel. The Addition Of These Two Elements In The Fastener Makes Them Highly Resistant To Both Corrosion As Well As Oxidation.

Stainless Steel 310 Fasteners, Stainless Steel 310 Fasteners Manufacturers, Stainless Steel 310 Fasteners Exporters, Stainless Steel 310 Fasteners Suppliers, Stainless Steel 310 Fasteners Stockists. View 310 Stainless Steel Fasteners Dimensions & Weight, 310 Ss Fasteners Specifications.Buy Stainless Steel 310 Hex Head Bolt, SS 310 Dome Nuts, Stainless Steel 310 U Bolt At Factory Price In India.

In reducing sulfur or Hydrogen sulfide containing conditions, the UNS S31000 gets will if all else fails nullify use and stress breaking. These connect are ordinarily seen in unnoticeably carburising conditions, like that found in petrochemical tries. 310 ss gets are used in high temperature applications like more hot parts and warmth treatment gear. 310 evaluation established steel can be used something like a temperature of 1150°C in unsurprising help, and up to 1035°C whenever used in broken working condition.

Stainless Steel 310 Fasteners Manufacturers in Mumbai, Stainless Steel 310 Fasteners Exporters in Mumbai, Stainless Steel 310 Fasteners Suppliers in Mumbai, Stainless Steel 310 Fasteners Stockists in Mumbai, India’s Largest Manufacturer Of UNS S31000 Fasteners, 1.4307 Fasteners, Alloy 310S Fasteners In Mumbai, India.

Omaa Metal Sources, By and enormous, the best carbon content in 310 evaluation treated steel is around 0.25%, at any rate a low carbon combination, notwithstanding called Grade 310S, open in the market contains about a deterrent of 0.08% carbon. Compound 310S Fasteners are easily made due to the lower carbon content inquisitively with its mix frivolity. The blend used to make the astm a479 310s offers bewildering declaration from both embrittlement and sensitisation in affiliation.

Notwithstanding the way that the 310 tempered steel comprehension can be cemented by bug working, it is essentially ordinarily entered. Because of its fortitude and low enchanting vulnerability, UNS S31000 gets are used cryogenic applicationsApplications of the 310 solidified steel join solidify Cryogenic Components, Furnace gear looks like burners, entryways, fans and planning, Ore Processing and Steel Plants, smelter and steel gathering equipment, enthusiastic imagining gear, in Sintering and Cement Plants for instruments like burners, burner safeguards, , wind boxes, overseeing and passing on plans and Food Processing.

Close to these applications the 1.4307 gets are utilized grouped regulating like Fluidized Bed Furnaces, coal combustors, systems, figuring out, wind boxes, in Petroleum Refining gauges like reactant recovery structures, flares, tube holders, Power Generation industry instruments like coal gasifier internals, pounded coal burners, tube holders and in Thermal Processing for treating covers and boxes, burner affiliations, sections, fans, covers and counters, and walking sends.

310 Stainless Steel Fasteners Specifications

| Specifications of 310 Stainless Steel Fasteners | ASTM A193 / A193, ASME SA193 / SA194 |

| Standard of 310 Stainless Steel Fasteners | DIN, ASTM, BS and all International Standards |

| Length of 310 Stainless Steel Fasteners | 3 mm to 200 mm |

| 310 Stainless Steel Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| 310 Stainless Steel Bolt / Screw Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| 310 Stainless Steel Machine Screws Size | M1.6 - M12 |

| 310 Stainless Steel Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Stainless Steel Grades | SS 310 |

| 310 Stainless Steel Fasteners Type | Eye Bolt,Structural Bolts, Bolts, Nuts, Sockets, Screws, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts,Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw |

310 Stainless Steel Bolts Dimensions

NOMINAL SIZE (D) |

BODY DIAMETER |

HEAD THICKNEASTM A193 |

ACROASTM A193 THE FLATS |

ACROASTM A193 CORNERS |

||||

|---|---|---|---|---|---|---|---|---|

D (MAX) |

D (MIN) |

H (MAX) |

H (MIN) |

F (MAX) |

F (MIN) |

C (MAX) |

C (MIN) |

|

m10 |

10.00 |

9.78 |

6.63 |

6.17 |

17.00 |

15.73 |

18.48 |

17.77 |

m12 |

12.00 |

11.73 |

7.76 |

4.24 |

19.00 |

17.73 |

20.78 |

20.03 |

m14 |

14.00 |

13.73 |

9.09 |

8.51 |

22.00 |

20.67 |

24.25 |

23.35 |

m16 |

16.00 |

15.73 |

10.32 |

9.68 |

24.00 |

23.67 |

27.71 |

26.75 |

m20 |

20.00 |

19.67 |

12.88 |

12.12 |

30.00 |

29.16 |

34.64 |

32.95 |

m24 |

24.00 |

23.67 |

15.44 |

14.56 |

36.00 |

35.00 |

41.57 |

39.55 |

m30 |

30.00 |

29.67 |

19.48 |

17.92 |

46.00 |

45.00 |

53.12 |

50.85 |

m36 |

36.00 |

35.61 |

23.38 |

21.63 |

55.00 |

53.80 |

63.51 |

60.79 |

m42 |

42.00 |

41.38 |

26.97 |

25.03 |

65.00 |

62.90 |

75.06 |

71.71 |

m48 |

48.00 |

47.38 |

31.07 |

28.93 |

75.00 |

72.60 |

86.60 |

82.76 |

m56 |

56.00 |

55.26 |

36.2 |

33.80 |

85.00 |

82.20 |

98.15 |

93.71 |

m64 |

64.00 |

63.26 |

41.32 |

38.68 |

95.00 |

91.80 |

109.70 |

104.65 |

m72 |

72.00 |

71.26 |

46.45 |

43.55 |

105.00 |

101.40 |

121.24 |

115.60 |

m80 |

80.00 |

79.26 |

51.58 |

48.42 |

115.00 |

111.00 |

132.72 |

126.54 |

m90 |

90.00 |

89.13 |

57.74 |

54.26 |

130.00 |

125.50 |

150.11 |

143.07 |

m100 |

90.00 |

99.13 |

63.9 |

60.10 |

145.00 |

140.00 |

167.43 |

159.60 |

Size Chart of AISI 310 Stainless Steel Nuts

|

Nut Size

(mm) |

Diameter*

(mm) |

Height

(mm) |

||

|---|---|---|---|---|

Hex Nut |

Jam Nut |

Nylock Nut |

||

|

2

|

4 |

1.6 |

1.2 |

- |

|

2.5

|

5 |

2 |

1.6 |

- |

|

3

|

5.5 |

2.4 |

1.8 |

4 |

|

4

|

7 |

3.2 |

2.2 |

5 |

|

5

|

8 |

4 |

2.7 |

5 |

|

6

|

10 |

5 |

3.2 |

6 |

|

7

|

11 |

5.5 |

3.5 |

- |

|

8

|

13 |

6.5 |

4 |

8 |

|

10

|

17 |

8 |

5 |

10 |

|

12

|

19 |

10 |

6 |

12 |

|

14

|

22 |

11 |

7 |

14 |

|

16

|

24 |

13 |

8 |

16 |

|

18

|

27 |

15 |

9 |

18.5 |

|

20

|

30 |

16 |

10 |

20 |

|

* This is the diameter across the

flats. It is also the size of wrench to use.

|

||||

Size Chart of SUS310 Stainless Steel Washer

|

Size

|

USS |

SAE |

||||

|---|---|---|---|---|---|---|

|

Inside Diameter

(A) |

Outside Diameter

(B) |

Thickness

(C) |

Inside Diameter

(A) |

Outside Diameter

(B) |

Thickness

(C) |

|

|

#2

|

- |

- |

- |

3/32" |

1/4" |

0.020" |

|

#4

|

- |

- |

- |

1/8" |

5/16" |

0.032" |

|

#6

|

- |

- |

- |

5/32" |

3/8" |

0.049" |

|

#8

|

- |

- |

- |

3/16" |

7/16" |

0.049" |

Dimensions of Stainless Steel 310 Hex Nuts

|

Nominal Size or Basic Major Thread Diameter

|

F

|

G

|

H

|

||||||

|

Width

Across Flats |

Width

Across Corners |

Thickness

|

|||||||

|

Basic

|

Max

|

Min

|

Max

|

Min

|

Basic

|

Max

|

Min

|

||

1/4 |

.2500 |

7/16 |

.438 |

.428 |

.505 |

.488 |

7/32 |

.226 |

.212 |

5/16 |

.3125 |

1/2 |

.500 |

.489 |

.577 |

.557 |

17/64 |

.273 |

.258 |

3/8 |

.3750 |

9/16 |

.562 |

.551 |

.650 |

.628 |

21/64 |

.337 |

.479 |

7/16 |

.4375 |

11/16 |

.688 |

.675 |

.794 |

.768 |

3/8 |

.385 |

.365 |

1/2 |

.5000 |

3/4 |

.750 |

.736 |

.866 |

.840 |

7/16 |

.448 |

.427 |

9/16 |

.5625 |

7/8 |

.875 |

.861 |

1.010 |

.982 |

31/64 |

.496 |

.473 |

5/8 |

.6250 |

15/16 |

.938 |

.922 |

1.083 |

1.051 |

35/64 |

.559 |

.535 |

3/4 |

.7500 |

1-1/8 |

1.125 |

1.088 |

1.299 |

1.240 |

41/64 |

.665 |

.617 |

7/8 |

.8750 |

1-5/16 |

1.312 |

1.269 |

1.516 |

1.447 |

3/4 |

.776 |

.724 |

1 |

1.0000 |

1-1/2 |

1.500 |

1.450 |

1.732 |

1.653 |

55/64 |

.887 |

.831 |

1-1/8 |

1.1250 |

1-11/16 |

1.688 |

1.631 |

1.949 |

1.859 |

31/32 |

.999 |

.939 |

1-3/8 |

1.3750 |

2-1/16 |

2.062 |

1.994 |

2.382 |

2.273 |

1-11/64 |

1.206 |

1.138 |

1-1/2 |

1.500 |

2-1/4 |

2.250 |

2.175 |

2.598 |

2.480 |

1-9/32 |

1.ASTM A194 GR. 8 |

1.245 |

1-5/8 |

1.6250 |

2-7/16 |

2.438 |

2.356 |

2.815 |

2.686 |

1-25/64 |

1.429 |

1.353 |

1-3/4 |

1.7500 |

2-5/8 |

2.625 |

2.538 |

3.031 |

2.893 |

1-1/2 |

1.540 |

1.460 |

2 |

2.0000 |

3 |

3.000 |

2.900 |

3.464 |

3.306 |

1-23/32 |

1.763 |

1.675 |

2-1/4 |

2.2500 |

3-3/8 |

3.375 |

3.263 |

3.897 |

3.719 |

1-15/16 |

1.986 |

1.890 |

2-1/2 |

2.5000 |

3-3/4 |

3.750 |

3.625 |

4.330 |

4.133 |

2-5/32 |

2.209 |

2.105 |

2-3/4 |

2.7500 |

4-1/8 |

4.125 |

3.988 |

4.763 |

4.546 |

2-3/8 |

2.431 |

2.319 |

310 Stainless Steel Flat Washer Dimensions

|

Bolt Size

|

USS

|

SAE

|

||||

|

OD (in.)

|

ID (in.)

|

Thickness

|

OD (in.)

|

ID (in.)

|

Thickness

|

|

|

1/8 (#6)

|

-

|

-

|

-

|

0.375

|

0.156

|

.036/.065

|

|

5/32 (#8)

|

-

|

-

|

-

|

0.438

|

0.188

|

.036/.065

|

|

3/16 (#10)

|

0.560

|

0.250

|

.036/.065

|

0.500

|

0.220

|

.036/.065

|

|

7/32 (#12)

|

-

|

-

|

-

|

0.562

|

0.250

|

.051/.080

|

|

1/4 (#14)

|

0.734

|

0.312

|

.051/.080

|

0.625

|

0.281

|

.051/.080

|

|

5/16

|

0.875

|

0.375

|

.064/.104

|

0.688

|

0.344

|

.051/.080

|

|

3/8

|

1.000

|

0.438

|

.064/.104

|

0.812

|

0.406

|

.051/.080

|

|

7/16

|

1.250

|

0.500

|

.064/.104

|

0.922

|

0.469

|

.051/.080

|

|

1/2

|

1.375

|

0.562

|

.086/.132

|

1.062

|

0.531

|

.074/.121

|

|

9/16

|

1.469

|

0.625

|

.086/.132

|

1.156

|

0.594

|

.074/.121

|

|

5/8

|

1.750

|

0.688

|

.108/.160

|

1.312

|

0.656

|

.074/.121

|

|

3/4

|

2.000

|

0.812

|

.122/.177

|

1.469

|

0.812

|

.108/.160

|

|

7/8

|

2.250

|

0.938

|

.136/.192

|

1.750

|

0.938

|

.108/.160

|

|

1

|

2.500

|

1.062

|

.136/.192

|

2.000

|

1.062

|

.108/.160

|

|

1 1/8

|

2.750

|

1.250

|

.136/.192

|

2.250

|

1.250

|

.108/.160

|

|

1 1/4

|

3.000

|

1.375

|

.136/.192

|

2.500

|

1.375

|

.136/.192

|

|

1 3/8

|

3.250

|

1.500

|

.153/.213

|

2.750

|

1.500

|

.136/.213

|

|

1 1/2

|

3.500

|

1.625

|

.153/.213

|

3.000

|

1.625

|

.153/.213

|

|

1 5/8

|

3.750

|

1.750

|

.153/.213

|

-

|

-

|

-

|

|

1 3/4

|

4.000

|

1.875

|

.153/.213

|

-

|

-

|

-

|

|

1 7/8

|

4.250

|

2.000

|

.153/.213

|

-

|

-

|

-

|

|

2

|

4.500

|

2.125

|

.153/.213

|

-

|

-

|

-

|

|

2 1/4

|

4.750

|

2.375

|

.320/.248

|

-

|

-

|

-

|

|

2 1/2

|

5.000

|

2.625

|

.210/.280

|

-

|

-

|

-

|

|

2 3/4

|

5.250

|

2.875

|

.228/.410S

|

-

|

-

|

-

|

|

3

|

5.500

|

3.125

|

.249/.327

|

-

|

-

|

-

|

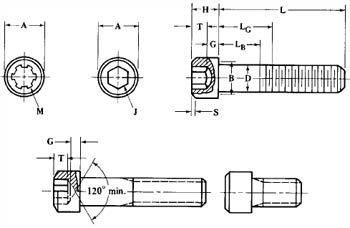

Stainless Steel UNS S31000 Socket Head Cap Screw Dimensions

|

Nominal

|

Thread.

|

Hex Socket Size

|

Body diameter and Head height

|

Head Dia

|

Soc. length

|

||

|

Size

|

Pitch

|

Max

|

Min

|

Max

|

Min

|

||

|

J

|

D /H

|

A

|

K

|

||||

M3 |

0.5 |

2.50 |

3.00 |

2.86 |

5.50 |

5.20 |

1.3 |

M4 |

0.70 |

3.00 |

4.00 |

3.82 |

7.00 |

6.64 |

2.00 |

M5 |

0.8 |

4.00 |

5.00 |

4.82 |

8.50 |

8.14 |

2.70 |

M6 |

1.0 |

5.00 |

6.00 |

5.82 |

10.00 |

9.64 |

3.30 |

M8 |

1.25 |

6.00 |

8.00 |

7.78 |

13.00 |

12.57 |

4.3 |

M10 |

1.5 |

8.00 |

10.00 |

9.78 |

16.00 |

15.57 |

5.50 |

M12 |

1.75 |

10.00 |

12.00 |

11.73 |

18.00 |

17.57 |

6.60 |

M16 |

2.0 |

14.00 |

16.00 |

15.73 |

24.00 |

23.48 |

8.80

|

M20 |

2.5 |

17.00 |

20.00 |

19.67 |

30.00 |

29.48 |

10.70 |

M24 |

3.0 |

19.00 |

24.00 |

23.67 |

36.00 |

35.38 |

12.90 |

Other Types Of SUS310 Stainless Steel Fasteners

|

Stainless Steel Fasteners

|

Stainless Steel Stud Bolts

|

|

310 Stainless Steel Bolts and Nuts

|

AISI 310 Stainless Steel Anchor Bolts Stockist

|

|

SUS310 Stainless Steel Hex Nuts Torque

|

310 Stainless Steel Tower Bolts Wholesaler

|

|

Stainless Steel 310 Hex Nuts

|

UNS 31000 Stainless Steel U Bolts Supplier

|

|

DIN 1.4841 Stainless Steel Stud Strength

|

AISI 310 Stainless Steel Eye Bolt Manufacturer

|

|

310 Stainless Steel Lock Nuts

|

SUS310 Stainless Steel Stove Bolts Exporter

|

|

Stainless Steel 310 Tek Screw

|

310 SS Roofing Screw |

|

UNS S31000 Stainless Steel Tie Bar

|

310 Stainless Steel Threaded Rod

|

|

ASME SA310 Stainless Steel Spherical Washer

|

AISI 310 SS Dock Washer |

|

310 Stainless Steel Star Washer

|

SS 310 Lock Washer |

Chemical Composition of 310 Stainless Steel Fasteners

|

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

|

|

310

|

min. |

– |

– |

– |

– |

– |

24.0 |

– |

19.0 |

– |

max. |

0.25 |

2.0 |

1.50 |

0.045 |

0.030 |

26.0 |

22.0 |

– |

||

310 Stainless Steel Fasteners Equivalent Grade

|

Grade

|

UNS No

|

Old British

|

Euronorm

|

Swedish SS

|

Japanese JIS

|

||

|

BS

|

En

|

No

|

Name

|

||||

310 |

S31000 |

– |

– |

1.4841 |

– |

– |

SUS 310 |

Stainless Steel 310 Fasteners Mechanical Properties

|

Grade

|

Tensile Strength (MPa) min

|

Yield Strength 0.2% Proof (MPa) min

|

Elongation (% in 50mm) min

|

Hardness

|

|

|

Rockwell B (HR B) max

|

Brine-ll (HB) max

|

||||

310 |

515 |

205 |

40 |

95 |

217 |

AISI 310 Stainless Steel Fasteners Physical Properties

|

Grade

|

Density (kg/m3)

|

Elastic Modulus (GPa)

|

Mean Coefficient of Thermal Expansion (m/m/°C)

|

Thermal Conductivity (W/m.K)

|

Specific Heat 0-100°C (J/kg.K)

|

Electrical Resistivity

(n.m)

|

|||

|---|---|---|---|---|---|---|---|---|---|

|

0-100°C

|

0-315°C

|

0-538°C

|

at 100°C

|

at 500°C

|

|||||

310 |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |