ASME B16.11 Threaded Tee, which is an enormous heap of resistant to substance use and oxidation (incapacitating safe), and has some high weight burst legitimacy and low complainer rates under high concerns at temperatures later sensible warmth treatment. Tempered Steel Threaded Equal Tee have a general delta and outlet sizes. Hung Tee Fittings are used in different endeavors applications like substance organizing, oil supervising plants, petrochemical and various affiliations.

Threaded Equal Tee,Threaded Equal Tee Manufacturers, Threaded Equal Tee Exporters, Threaded Equal Tee Suppliers, Threaded Equal Tee Stockists,Threaded Equal Tee Manufacturers, Threaded Equal Tee Exporters, Threaded Equal Tee Suppliers, Threaded Equal Tee Stockists.

We producer of Stainless Steel Threaded Equal Tee. We are making SS 310 Threaded Tee, ASME B16.11 Threaded Tee, Hastelloy C22 Forged Pipe Tee and 3000LB Threaded Equal Tee expecting basically no work by excellence of reasonable specialist hours in India and noteworthy wellspring of best in class Threaded Tee, most ideal situation, cost open in Mumbai, India.

We are Manufacturer of Threaded Tee Fittings comprehended by Saudi Aramco. We keep up wide heap of Screwed Tee.Omaa Metal Sources stock inside and out level of Threaded copper Tee, NPT Threaded tee in Stock in various sizes.

Accepting you are hoping to buy Alloy Steel Forged Screwed Tee and Stainless Steel Threaded Equal Tee, most ideal situation, cost in India, check our expense of Forged Threaded Tee including ASTM A182 SS Threaded Tees, A350 Gr LF2 Screwed Tee and NPT Pipe Tee.

Steel Mart India is giving Threaded Equal Tee to UK, USA, Sweden, Israel, France, Italy, Canada, UAE, Australia, Germany, Russia, Oman, Kuwait, Qatar, Iran, Turkey, Egypt, Bahrain, Indonesia, Malaysia, Singapore, Thailand, Sri Lanka and Saudi Arabia.

We can deftly Threaded Fittings Tee, most ideal situation, cost as we are perhaps the most uncommon supplier and carrier of BS3799 Screwed Forged Equal Tee in Indium. We have our stocking dealers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ASTM A105 NPT Threaded Tee cost prior to buying ANSI B16.11 Forged Threaded Tee from India or China. other than mail for our live successfully of Forged Threaded Equal Tee to check types and sizes with our planned stock we can give you best expense of Nickel Alloy 200 Equal Tee.

Threaded Equal Tee Manufacturers in Mumbai, Threaded Equal Tee Exporters in Mumbai, Threaded Equal Tee Suppliers in Mumbai, Threaded Equal Tee Stockists in Mumbai.

Specification of Threaded Equal Tee

| Specifications | Forged Threaded equal tee |

|---|---|

| Dimension Specification | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Threaded equal tee Forged Fittings Thread | NPT, BSPT, BSPP |

| Threaded equal tee FittingsType | DN15-DN1200 |

| End | Threaded, Welding, JIC |

| Threaded equal tee Fittings Pressure Rating | Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Threaded equal tee |

| Size Range | 1/8" NB TO 4" NB |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Threaded equal tee Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Threaded equal tee Fittings |

|

| Application |

|

Material of Threaded Equal Tee

| Carbon Steel Threaded Equal Tee | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel Threaded Equal Tee | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel Threaded Equal Tee | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Threaded Equal Tee | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Threaded Equal Tee | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Threaded Equal Tee | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass Threaded Equal Tee | 3602 / 2604 / H59 / H62 / etc. |

| Inconel Threaded Equal Tee | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Threaded Equal Tee |

| Hastelloy Threaded Equal Tee | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel Threaded Equal Tee | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Threaded Equal Tee | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Threaded Equal Tee | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Threaded Equal Tee | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Threaded Equal Tee | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Threaded Equal Tee | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy Threaded Equal Tee | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo Threaded Equal Tee | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Threaded Equal Tee | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other Threaded Equal Tee material | Tin bronze, Alumunum bronze, Lead bronze |

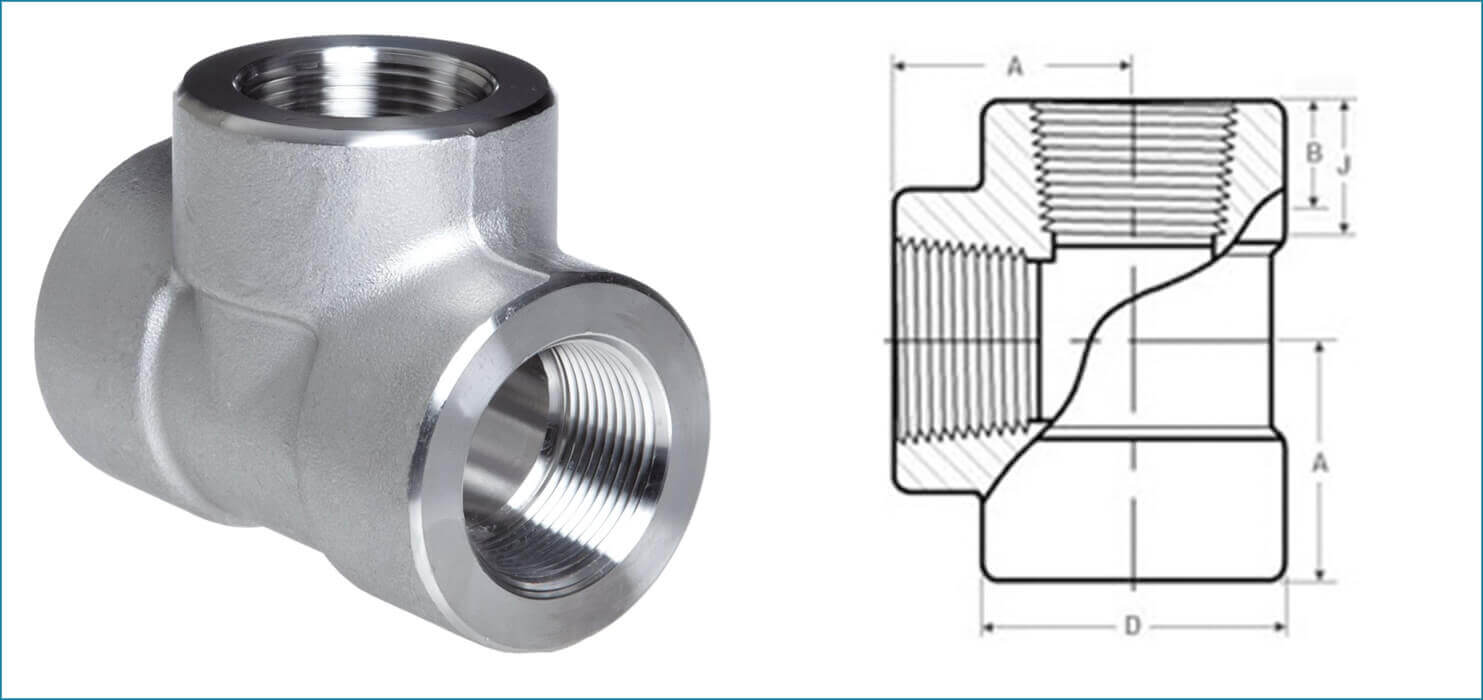

Dimensions of Threaded Equal Tee

| Class 2000 | Nominal Pipe Size |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | – | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0.267 | 0.373 | 0.613 | 0.963 | 1.355 | 2.030 | 2.800 | 4.456 | 9.530 | 12.908 | 28.700 | |

Class 3000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.325 | 0.460 | 0.753 | 1.270 | 1.830 | 3.025 | 3.620 | 7.040 | 7.550 | 13.125 | 23.100 | 40.000 | |

Class 6000 |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0.500 | 0.853 | 1 410 | 2.150 | 3.563 | 4.625 | 7.625 | 9.625 | 18.500 | 28.063 | 47.500 | 50.000 | |