Solidified Steel High Pressure Pipe Fittings. SS high crushing component pipe fittings are introduced in various achievements, rules, nuances, errands. We in addition give customers customization choices so they can demand any remarkable sorts of line fittings according to their application fundamentals. These high crushing element pipe fittings are completely utilized over the undertakings for both standard kind of stuff in any case, for creation purposes. We hold a wide bundle of high pressing element pipe fittings to achieve each fundamental made by our clients. The undesirable materials utilized in the gathering cycle are acquired from trusted and fair transporters that guarantee its handiness. We give outright idea to keep up the quality concentrations to make extended length business relationship with clients.

High Pressure Pipe Fittings, High Pressure Pipe Fittings Manufacturers, High Pressure Pipe Fittings Exporters, High Pressure Pipe Fittings Suppliers, High Pressure Pipe Fittings Stockists.

High Pressure Pipe Fittings Manufacturers in Mumbai, High Pressure Pipe Fittings Exporters in Mumbai, High Pressure Pipe Fittings Suppliers in Mumbai, High Pressure Pipe Fittings Stockists in Mumbai.

We are overhauled with unimaginably progressed gadget and master work power, using them we guarantee essentially ruling quality things are made in our social affair unit. Tempered Steel High Pressure Pipe Fittings are totally expected for association in wet conditions. This appraisal has remarkable comfort to the degree intergranular assaults. The SS high pressing component pipe fittings can be revealed in an opening and pitting use in conditions that contain a raised level of decreasing educated authorities. Additionally, this appraisal is weld able with all sort of standard welding measure even with or without filler materials.

How Stainless Steel High Pressure Pipe Fittings are done?

The produced scope of line fittings is handled under standard completing technique like hot factory spotless and blue with a type of hot moving cycle. The high pressing factor pipe fittings require stock evacuation to lessen conceivable surface mistakes may show up from the assembling cycle. Commonly, these are unpleasant diverted used to eliminate stock from oversize fittings by going approx to the necessary size. The size of cold worked pipe fittings is frequently utilized in the application without a surface completion. The cleaned and turned line fittings are made to a similar resilience as the virus worked; besides, this is produced by cleaning and turning tasks. These line fittings are both virus drawn and cold wrapped up. Notwithstanding, these colds completed line fittings properties are equivalent to the standard grade. The virus working activity grants increment in mechanical properties. The pounding cycle brings tight resistance breaking point and cleaned to get a splendid completion.

Nature of treated steel high pressing factor pipe fittings:

We are rumored exporter and provider of top of the line pipe fittings, which are adjusted with worldwide principles utilizing the high level apparatuses and hardware that guarantees the nature of line fittings. Various tests are performed by us those are substance sythesis examination, hydro testing, dangerous test, pressure test, intergranular consumption test, spillage test, radiography, pitting erosion test, and ultrasonic test.

How Stainless Steel High Pressure Pipe Fittings are stuffed?

The high pressing factor pipe fittings are stuffed and conveyed in the standard pressing to give 100% harm free transportation. We pack these line fittings in the wooden cases, pressed wood containers, beds, and boxes with plastic cap uphold, additionally to shield tainting from rusting the pressing is covered with a dainty film of plastic.

Size Range :

1/16” to 2”

End Connections :

NPT, BSP, & BSPT.

Stainless Steel High Pressure Pipe Fittings

- Stainless Steel 304 High Pressure Pipe Fittings

- Stainless Steel 304L High Pressure Pipe Fittings

- Stainless Steel 304H High Pressure Pipe Fittings

- Stainless Steel 310 High Pressure Pipe Fittings

- Stainless Steel 316 High Pressure Pipe Fittings

- Stainless Steel 316L High Pressure Pipe Fittings

- Stainless Steel 316H High Pressure Pipe Fittings

- Stainless Steel 316Ti High Pressure Pipe Fittings

- Stainless Steel 317 High Pressure Pipe Fittings

- Stainless Steel 321 High Pressure Pipe Fittings

- Stainless Steel 347 High Pressure Pipe Fittings

- Stainless Steel 904L High Pressure Pipe Fittings

Duplex Steel High Pressure Pipe Fittings

- Duplex Steel S31803 / S32205 High Pressure Pipe Fittings

- Super Duplex Steel S32750 / S32760 High Pressure Pipe Fittings

High Nickel Alloy High Pressure Pipe Fittings

Nickel Alloy High Pressure Pipe Fittings

- Nickel Alloy 200 High Pressure Pipe Fittings

- Nickel Alloy 201 High Pressure Pipe Fittings

Monel High Pressure Pipe Fittings

- Monel 400 High Pressure Pipe Fittings

- Monel K500 High Pressure Pipe Fittings

Hastelloy High Pressure Pipe Fittings

- Hastelloy C22 High Pressure Pipe Fittings

- Hastelloy C276 High Pressure Pipe Fittings

Inconel High Pressure Pipe Fittings

- Inconel 600 High Pressure Pipe Fittings

- Inconel 601 High Pressure Pipe Fittings

- Inconel 625 High Pressure Pipe Fittings

- Incoloy 800 High Pressure Pipe Fittings

- Incoloy 825 High Pressure Pipe Fittings

Titanium High Pressure Pipe Fittings

- Titanium Gr 2 High Pressure Pipe Fittings

- Titanium Gr 5 High Pressure Pipe Fittings

Carbon Steel High Pressure Pipe Fittings

- Carbon Steel A105 High Pressure Pipe Fittings

- Alloy Steel High Pressure Pipe Fittings

Brass High Pressure Pipe Fittings

- IS-319 / BS - 218 High Pressure Pipe Fittings

Other

- SMO 254 High Pressure Pipe Fittings

- Alloy 20 High Pressure Pipe Fittings

Products

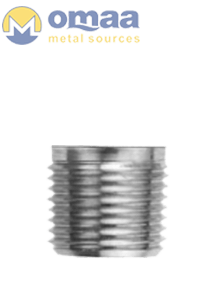

Close Nipple

Hex Nipple

Hex Reducing Nipple

Hex Long Nipple

Reducing Adapter

Reducing Bushing

Hex Coupling

Hex Reducing Coupling

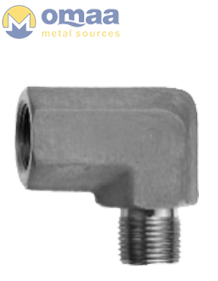

Elbow Female

Elbow Reducing Street

Male Elbow

45° Elbow Female

45° Elbow Street

Tee Female

Tee Street

Tee Branch

Tee Male

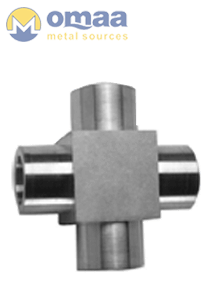

Cross Female

Union Ball Joint

Hex Female Cap

Hex Male Plug

Allen Plug

Hex SAE Plug

Allen SAE Plug

SAE Adapter

Hex Pipe Plug

Gauge Adapter

Male Connector

Female Elbow

Union Cross

Female Connector – FF

Union

Union Elbow

Male Adaptor NPT