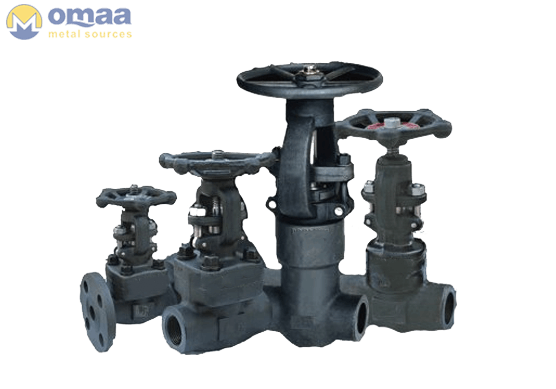

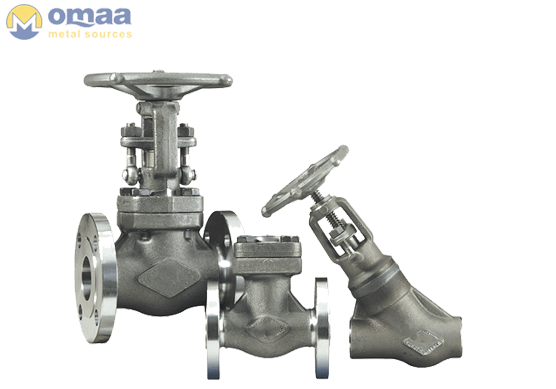

We are Stainless steel 304 Forged Steel Valves. We as a producer, supplier, exporter and stockiest are offering something basically the same as both worldwide and private buyers. The offered extents of thing are particularly made by using the high review material and by considering the moved techniques to meet the connected fundamental of their clients. Also, these are adequately open to overall buyers as it is generally speaking passed on.

Forged Steel Valves, Forged Steel Valves Manufacturers, Forged Steel Valves Exporters, Forged Steel Valves Suppliers, Forged Steel Valves Stockists.

Forged Steel Valves Manufacturers in Mumbai, Forged Steel Valves Exporters in Mumbai, Forged Steel Valves in Mumbai, Forged Steel Valves Stockists in Mumbai.

It is having the piece of wonderful parts like they are strong to use and shrewd. The thing is proposed to the buyers at different subtleties as per the necessities of the client base. Concerning the worldwide and public nature of harsh materials, the thing is likewise introduced by the specific sales of the clients for express applications. It is made open to the buyers at different sorts, pressure examinations, temperature rating, end affiliations, working strain, sizes, standards, etc.

Alloy details: Stainless steel 304 is the commonly used stainless steel alloy and this steel is having both nickel and chromium metals as the major non-iron elements. This steel is austenitic stainless steel that is thermally and electrically conductive than the other alloys and it is nonmagnetic. It is very good corrosion resistance than the regular steel and it is used widely in many industrials applications due to the ease of fabrications.

Manufacturing process: There at the production unit, the development of it is executed by using the very good quality of alloy that is well tested. There at the industry, the manufacturing of all ranges of Stainless steel 304 Forged Steel valves is done under the strict guidance of professional expert’s team. Also, the use of latest technology and modern tools help the manufacturers in developing the very good quality of valves that is demanded by the industrialists as per the demands they have made.

Additionally to prove product quality standards, the producers are considering national and international; product standards. There at the manufacturing unit quality control team is appointed that is assigned with the task of looking at the product quality through quality control measures. The testing of the manufactured ranges of Stainless steel 304 Forged Steel valves is conducted essentially in order to supply the superior quality of product to the buyers. Few tests like hardness test, mechanical test, chemical test, pitting resistance test, ultrasonic test, radiography test, etc conducted. To the buyers the documents are offered are like fumigation certificate, commercial invoice, packaging list, heat treatment chart, quality assurance plan, material traceability report, guarantee letter, etc. Also, the test certifications offered to the buyers are like 100% radiography test report, third-party test report, mill test certificate as per En 10204/3.1B, buyers report and buyers report are the offered documents.

Packaging: At the dispatch section, the packaging of Stainless steel 304 Forged Steel valves is done by using wooden cases, polypropylene sheets, etc. This assures safer shipping of the product.

Specification

End Connections: Screwed / Socket Weld / Butt Weld End

Working Pressure: 800# / 1500#

Face To Face: ANSI B 16.10

Socket Weld End: ANSI B 16.11

Butt Weld End: ANSI B 16.25

Screwed End:ANSI B 1.20.1(BSP/NPT)

EQUIVALENT GRADES

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

CHEMICAL PROPERTIES

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | - | 8 – 11 | - |

Stainless Steel Forged Valves

- Stainless Steel 304 Forged Valves

- Stainless Steel 304L Forged Valves

- Stainless Steel 304H Forged Valves

- Stainless Steel 310 Forged Valves

- Stainless Steel 316 Forged Valves

- Stainless Steel 316L Forged Valves

- Stainless Steel 316H Forged Valves

- Stainless Steel 316Ti Forged Valves

- Stainless Steel 317 Forged Valves

- Stainless Steel 321 Forged Valves

- Stainless Steel 347 Forged Valves

- Stainless Steel 904L Forged Valves

Duplex Steel Forged Valves

- Duplex Steel S31803 / S32205 Forged Valves

- Super Duplex Steel S32750 / S32760 Forged Valves

High Nickel Alloy Forged Valves

Nickel Alloy Forged Valves

- Nickel Alloy 200 Forged Valves

- Nickel Alloy 201 Forged Valves

Monel Forged Valves

- Monel 400 Forged Valves

- Monel K500 Forged Valves

Hastelloy Forged Valves

- Hastelloy C22 Forged Valves

- Hastelloy C276 Forged Valves

Inconel Forged Valves

- Inconel 600 Forged Valves

- Inconel 601 Forged Valves

- Inconel 625 Forged Valves

- Incoloy 800 Forged Valves

- Incoloy 825 Forged Valves

Titanium Forged Valves

- Titanium Gr 2 Forged Valves

- Titanium Gr 5 Forged Valves

Carbon Steel Forged Valves

- Carbon Steel A105 Forged Valves

- Alloy Steel Forged Valves

Brass Forged Valves

- IS-319 / BS - 218 Forged Valves

Other

- SMO 254 Forged Valves

- Alloy 20 Forged Valves

Products

Forged Steel Globe Valve

Forged Steel Gate Valve

Forged Steel Flanged End Valves

Forged Steel Check Valves

Forged Extended Body Valves

Forged Steel Y-PATTERN Valves

Forged Steel Cryogenic Valve